GPC automation design project: new generation insulin injection pen

2020-08-27

Are you always concerning about the laboring maintenance or your product competition regarding to the Quality, Cost issues and the promise for the On-time Delivery?

GPC will be your best selective partner to reduce your laboring request and keep your products with consistent Quality, lowest Cost and plannable delivery through our Automation design.

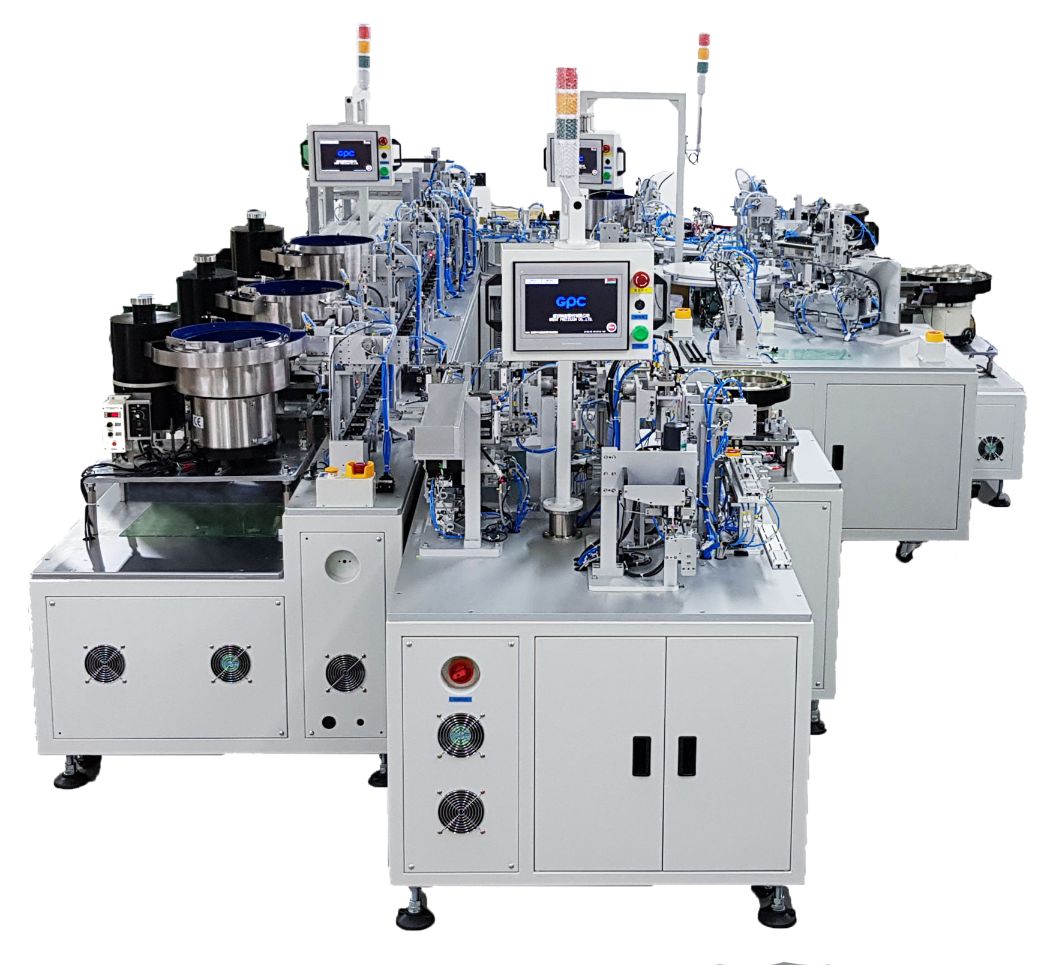

Project: new generation insulin injection pen

▌Machine capability:600UPH.

▌Machine functions:

To integrate five automatic assembly machines, which handling the complex injection pen assembly process automatically, the whole motions were connected each other through the equipment interface.

Total of 20 various types of parts were fed into the machine through the vibration bowl / linear feeder or stacker, which included:

- There are four parts in the machine #1 pen body/ball screw/ratchet and the nylon gasket.

- There are three parts in the machine #2 threaded sleeve/threaded rod and lock cap.

- There are five parts in the machine #3 large sleeve rod/short sleeve rod/small sleeve rod/button and button spring.

- There are six parts in the machine #4 anti-return spring/ anti-return gasket/ bottom spring/ large ratchet/ adjusting spring and middle ratchet.

- There are two parts in the machine #5 adjusting ratchet and adjusting knob.

The equipment was designed by the quick model change according to the different injection functional parts.

The final assembly pen will be able to arrange and stack into the tray specified by the customer, and the stacking quantity can be set follow up the customer’s demand.

GPC provides the total solutions for the implementation of automatic parts assembly, Inspection, testing and data collection & analysis.

Booth No. L1004